-

Handheld Inkjet Printer

-

Industrial Inkjet Printer

-

Laser Marking Machine

-

Coding And Marking Machine

-

High Resolution Inkjet Printer

-

Thermal Inkjet Printer

-

Portable Inkjet Printer

-

Large Character Inkjet Printer

-

Laser Welding Machine

-

Laser Cleaning Machine

-

Laser Cutting Machine

-

Sticker Labeling Machine

-

Paging Machine

-

Food Packaging Conveyor Belt

-

Visual Inspection Machine

-

Printer Consumables

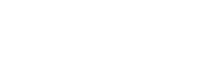

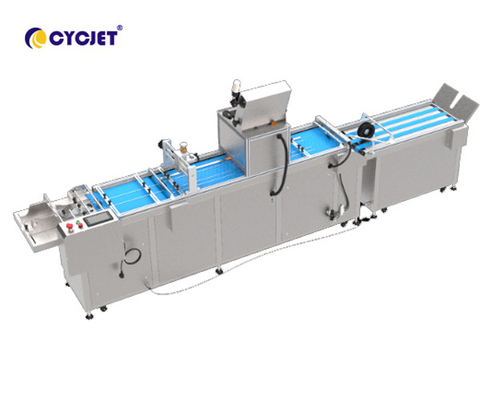

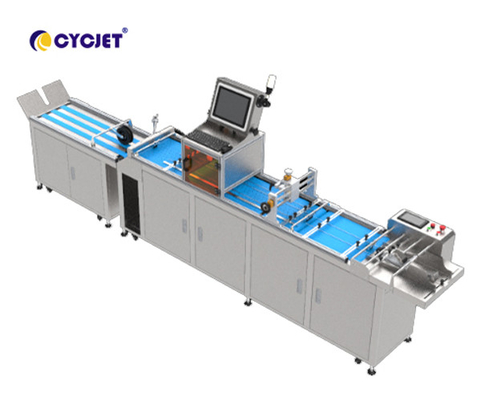

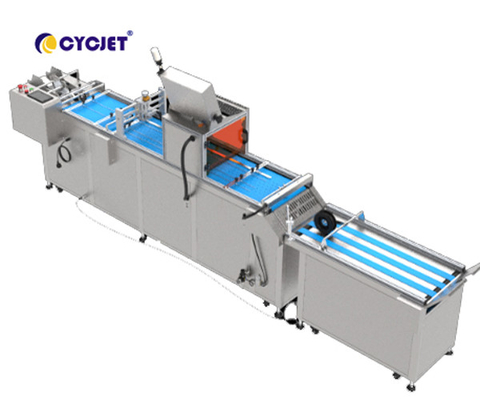

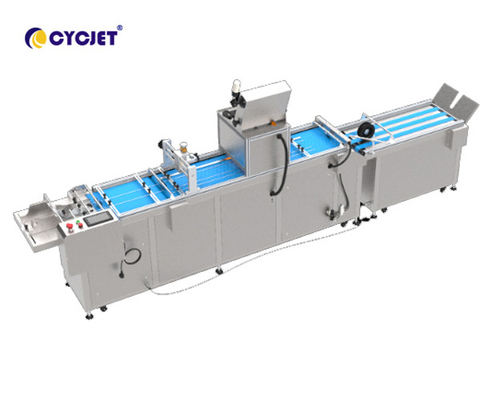

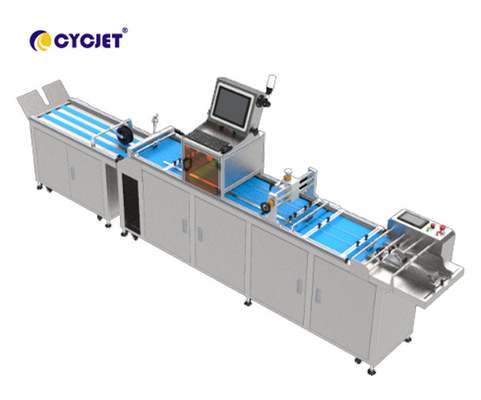

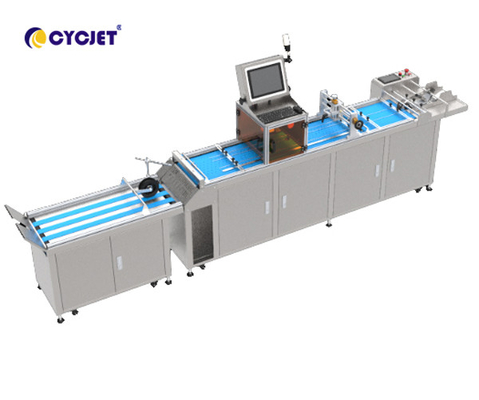

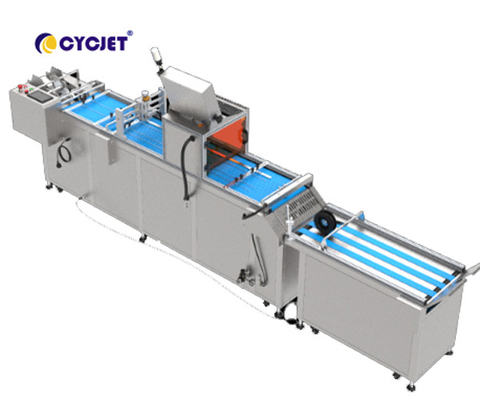

CYCJET CVI 450-VD Automated Visual Inspection Machine For Coding Machine

| Name | CVI450-VD Visual Inspection System For Coding Machine | Power Consumption | 440W |

|---|---|---|---|

| Paging Belt Width | 60mm | Paging Width | 80-380mm |

| Paging Length | 50-320mm | Speed | 30-100m/min |

| Paging Offset | ±0.5-2mm(depend On Products) | Air Source | 0.4Mpa |

| Highlight | CVI 450-VD Visual Inspection Machine,CYCJET Visual Inspection Machine,bags automated visual inspection systems |

||

Description of CYCJET CVI450-VD Visual Inspection System for Coding Machine:

Application:

Cards, bags, labels, boxes, etc.

Usage:

The finished product is formed into a single sheet through the page header and sent to the lower station for coding, thereby reducing manual labor and greatly improving production efficiency and coding accuracy. Due to the physical characteristics of the product, the splitting process will have the probability of overlapping (overlapping) after the re-inspection device station will alarm and stop independently (no coding and visual confusion will be caused by the shutdown, and the two conveyor belts will operate independently) . The coding mark needs to be checked visually, and it must be checked with duplicate sheets. In the case of complete duplication, (coding) is only printed on the first material above, and the visual detection cannot detect the following product. , which results in the phenomenon of leaking and leaking. In the parameter modification interface of the operation screen, there are two kinds of settings: "Redraw Stop" and "Redraw Run". The function of double-stretching operation means that double-stretching is detected in real time but the line is not stopped, and the signal is transmitted to the back-end flap for elimination. Note: This function will cause waste of products (for example, if the double sheet is two misplaced, at this time, the marking and coding equipment will also code normally, resulting in inaccurate coding). Marking equipment such as small character inkjet printers, laser machines, UV, high-resolution inkjet printers and other supporting equipment malfunctioned during work, resulting in leaks and leaks, and the speed of rice noodles was very fast. Using visual inspection device to replace manual inspection greatly improves production efficiency. Visual inspection has three functions: the detection function of the number of characters, the OCR detection function of characters, the detection function of scanning and reading QR code and barcode, the detection function of the number of characters is for the detection of missing codes and missing codes, and the OCR detection function of characters It is for character stroke typo detection.

Control system function software features:

All Chinese prompt information, simple operation, comprehensive functions, easy to use

With power-off protection function, parameter data is permanently saved

You can set parameters, choose a variety of parameters, and switch at will

With alarm and prompt function

Features of Overload Detection System:

Set the resize value according to the thickness of the bag

The double sheet detection will stop immediately, and the accuracy rate is ≥ 99.99%

The re-sheet can move forward freely, and exit to take out the re-sheet sample

Reduce manual judgment, intelligent, energy-saving production

Features of the Vision System

Applicable to: ink coding, laser coding detection, high-resolution coding detection and other coding equipment coding detection, it can detect whether the coding characters are more sprayed, less sprayed, missing spraying, sprayed crookedly, and the coding exceeds the area; bar code detect

Product running posture: stable, no obvious deviation, uniform coding position

Detection accuracy: more than 1/2 of a single character is missing, the detection rate is ≥99.99%, and the rejection rate is ≥99.99%

Automatic rejection function: The rejection rate of the unqualified products detected by the system is ≥99.99%, and the rejection position is uniform and accurate. The system can set if several items are rejected continuously, the system will continuously alarm to remind the operator to find out the reason.

| CVI450-VD Visual Inspection System | |

| Model | CVI450-VD |

| Power Voltage | AC220V-50/60HZ(grounding wire necessary) |

| Power Consumption | 440W |

| Paging Belt Width | 60mm |

| Paging width | 80-380mm |

| Paging Length | 50-320mm |

| Paging Thickness | 0.05-5mm |

| Speed | 30-100m/min |

| Conveyor Width | 350mm |

| Conveyor Length | Overlapping detection:455mm, Coding Detection:1450mm |

| Dimension | 3820X620X920mm |

| Conveyor direction | Single direction |

| Paging offset | ±0.5-2mm(depend on products) |

| Working Environment | Temperature:-10-40℃, Relative Humidity:75% |

| Air Source | 0.4Mpa |

| Unqualified Products Handle | Automatic Remove |

| Reverse Board Remove | After detecting unqualified products, remove them according to the delay time |

| Conveyor Belt Color | Blue |

![]()

FAQ

Q1: Do you have own factory ?

We have establishes factory since 2011. We are located in Shanghai ,China.

Q2: Could you help me to operate the machine ?

Sure ,we will send you an operation file and some videos how to operate it.ou also can contact our salesman to teach you face to face on Whatsapp.

Q3: How long the cartridge can be used ?

We use hp45 ink cartridge,45ml, it can print about 10 thousands time for date code,it depend on the size and ink quantity of characters.

Q4: Do you support OEM/ODM?

Yes, we can develop the styles base on customer's requirement and put your logo on the editing interface or the machine .

Q5: How to ensure that I received the machine undamaged?

Firstly, our package is a protector for shipment, we must confirm machines are undamaged before delivery, and we've bought insurance for you, we will take the responsibility if machines damaged.

Q6: what is your after-sale service for that machine?

My friend,we will offer professional stuff for after-sale service ,you can give our a call or video call to express your problem

so that we can help you,and we set up one year warranty for the machine

![]()