-

Handheld Inkjet Printer

-

Industrial Inkjet Printer

-

Laser Marking Machine

-

Coding And Marking Machine

-

High Resolution Inkjet Printer

-

Thermal Inkjet Printer

-

Portable Inkjet Printer

-

Large Character Inkjet Printer

-

Laser Welding Machine

-

Laser Cleaning Machine

-

Laser Cutting Machine

-

Sticker Labeling Machine

-

Paging Machine

-

Food Packaging Conveyor Belt

-

Visual Inspection Machine

-

Printer Consumables

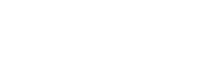

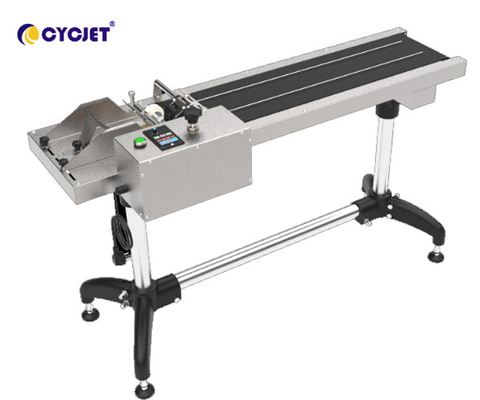

CPG 320 Inverted Paging Machine CYCJET Paper Auto Card Feeder Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | CPG320 Inverted Paging Machine For Labels Paper Card Auto Feeder Machine | Power Voltage | AC220V-50/60HZ(grounding Wire Necessary) |

|---|---|---|---|

| Power Consumption | 120W | Paging Belt Width | 40mm |

| PPaging Width | 5-320mm | Paging Length | 40-290mm |

| Paging Thickness | 0.1-5mm | Speed | 30-80m/min |

| Dimension | 1310X430X900mm | ||

| Highlight | CPG 320 Paging Machine,120W Inverted Paging Machine,CYCJET paper auto card feeder machine |

||

CPG320 Inverted Paging Machine For Labels Paper Card Auto Feeder Machine

Application:

CYCJET Paging macine application for Cards, bags, labels, boxes, etc.

Paging Machine Usage:

Place the stacks of paging objects on the paging head and run through the reversing wheel, and transfer the paging objects to the conveyor belt in the form of a single page (single), which is convenient for the synchronous work of the inkjet printer, laser machine, labeling machine and other related equipment. , such as inkjet printing date code, laser printing graphic information, labeling product labels and other automatic supporting facilities, thereby reducing the cumbersome manual paging, giving full play to the high-speed printing advantages of inkjet printers and laser machines to improve printing efficiency and convenience. Production operation and management

Features of Pagination Machine:

1. Frequency conversion speed regulation, high-speed automatic paging 60-600 pieces/min

2. High paging speed, high positioning accuracy and high production efficiency

3. Qualified structural design, independent shaft, easy and fast replacement of wearing parts

4. Optional accessories: static elimination device, receiving hopper, etc.

| CPG320 Inverted Paging machine | |

| Model | CPG320 |

| Power Voltage | AC220V-50/60HZ(grounding wire necessary) |

| Power Consumption | 12W |

| Paging Belt Width | 40mm |

| Paging width | 5-320mm |

| Paging Length | 40-290mm |

| Paging Thickness | 0.1-5mm |

| Speed | 30-80m/min |

| Conveyor Width | 230mm |

| Conveyor Length | 960mm |

| Dimension | 1310X430X900mm |

| Conveyor direction | Single direction |

| Controller | Frequency Control |

| Power Unit | Three-Phase asynchronous motor |

| Power Protection | 6A AC integral socket with fuse |

| Appearance | Stainless Steel Polishing |

| Materials | Stainless Steel, Industrial section steel |

| Floor Stand | Adjustable base |

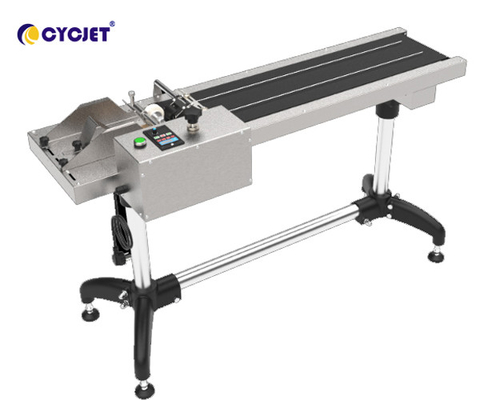

Paging Machine Drawing:

![]()

FAQ:

What is used for?

This paging system can automatically separate stacks of bags and convey single piece onto the conveyor belt so as to facilitate label applicator to stick each sticker onto bags and thus reduce the trifles of manual paging to improve labeling efficiency.

This is a feeder and dispenser system which feeds labels, pouch, cards, plastic bags, sheet paper or other flat objects at high speed on the conveyor. It automatically separate/split/divide stacks of pouches into single piece and deliver to the conveyor belt so as to facilitate ink-jet printer, laser coding machine to spray batch number, logo, anti-fake mark, pattern, QR, and bar code on packages. It also is good auxiliary equipment for label applicator to finish accuracy and high efficiency labeling working.

Features:

1. Multipurpose machine which can be matched with ink jet printer, laser coding machine, labeling machine or vision camera system.

2. Reduce the trifles and of manual paging and feeding, make full use of the advantages of accuracy and high-speed spray printing and sticker labeling.

3. Can be equipped with the function of intelligent counting and automatic stop to facilitate production management.

4. Reasonable structural design can be easier to replace damageable parts.

How does it work?

Using the most advanced paging technology, bunch or stack of products are placed in the feeding tray in this machine and get fed by a rotating friction wheel, the bottom bag will get fed first. The fed bag then moved forward by chains & rubber belt from one side to the other end side.

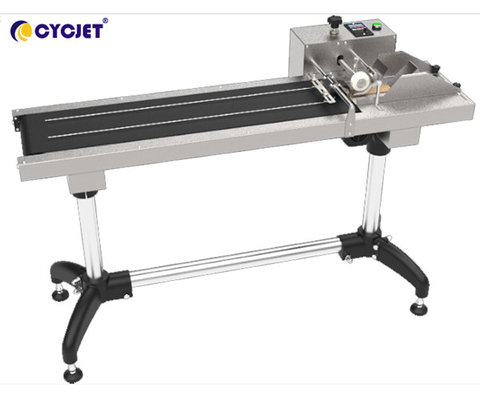

Pagination Machine Details:

![]()

Company Showing:

![]()